yes you can use a drum sander on a drill press but break down and by the oscillating spindle sander anyway. you wont regret it

| Official Luthiers Forum! http://w-ww.luthiersforum.com/forum/ |

|

| Sanding inside a mold. http://w-ww.luthiersforum.com/forum/viewtopic.php?f=10102&t=6086 |

Page 1 of 2 |

| Author: | Colby Horton [ Tue Apr 11, 2006 1:11 am ] |

| Post subject: | |

I'm planning on making my own building mold soon. I'm planning on glueing up three or four pieces of 3/4" plywood and cutting down the center so I have two halves. I'm planning on cutting out the outline just shy of my line and then sanding it true. Here's where my question comes in. Could I use my drill press with a big sanding drum to sand the outline or should a break down and buy a decent oscillating spindle sander. Grizzly has one for about $200.00 I've never used a big drum on my drill press before but I have used some small ones. It seems to clog quickly and heat up quickly and I just don't know if it would work to well. |

|

| Author: | Michael Dale Payne [ Tue Apr 11, 2006 1:13 am ] |

| Post subject: | |

yes you can use a drum sander on a drill press but break down and by the oscillating spindle sander anyway. you wont regret it

|

|

| Author: | LanceK [ Tue Apr 11, 2006 1:19 am ] |

| Post subject: | |

Or, send your tracing to John Hall, and he'll make you a great outside mold. By the time you get the wood, time and toggles, sanding disks etc, your not saving much if any. Now dont get me wrong, IF you wanna make it your self, by all means do!

|

|

| Author: | Colin S [ Tue Apr 11, 2006 1:23 am ] |

| Post subject: | |

Colby, by far the best way of making your own mould is to make a plywood template of half the guitar and use a pattern following router cutter to cut the shape out. I use 3/4" MDF, band sawn roughly to shape, attach the pattern (I use small screws as being more reliable than double sided tape) and run it across the router bit in my router table. That way you guarentee to get 8 identical pieces to glue up for the mould that have beautiful crisp edges. I recommend gluing the sections together one at a time rather than the stack of four as it's much easier to get the alignment right. I did my first couple using the drum sander and would not go back to that way if you paid me a lot of money! Colin |

|

| Author: | L. Presnall [ Tue Apr 11, 2006 1:26 am ] |

| Post subject: | |

Send the tracing to John, AND buy the tool!

|

|

| Author: | Bruce Dickey [ Tue Apr 11, 2006 2:47 am ] |

| Post subject: | |

Save your money on the spindle sander. I consider my Jet spindle sander the worst investment in my shop for acoustic guitar making. Here is why, it digs troughs. You'd need something akin to a conveyor to pull it against the spindle steadily and evenly to get good results. You probably have a router, a twenty dollar pattern following router bit is the way to build molds. Check out two sources, Hoffman and Matsushita for mold building. There you get the solid built up mold like Hoffman, or the block filled method with top and bottom setup like Matsushita. I took Kathy's idea of the 1/4 hardboard masonite and use that for a pattern, then countersink some cabinet hardware screws into blanks of 3/4 inch plywood cut proud on a band saw and trimmed back on a router table. So I combined the two methods and build a pretty nice mold. The purpose for the pattern is to be able to build more, you just need one half pattern, use it on both sides. Good luck, whatever method you choose, Colby. |

|

| Author: | Bruce Dickey [ Tue Apr 11, 2006 2:54 am ] |

| Post subject: | |

Colin and I agree on the pattern. Here is one twist Hoffman adds to keep all pieces identical. Toss the pattern after making two identical sides, attach the blanks to the actual first cut piece. I glue and screw proud blanks to that piece and route away. By using tempered sheet rock screws you really don't have to use clamps, but I do anyway to get excess glue out of the joint. Again, Good luck with the process, it's fun and rewarding. I have one mold that I built on 9/11/02, each time I pick it up I see the notation: "We will Never Forget." And I won't as long as I build guitars with that mold. PS I too like Colin use the stability and convenience of the router table, what a great tool for every shop building guitars. I use it all the time, especially for neck work. |

|

| Author: | Michael Dale Payne [ Tue Apr 11, 2006 4:25 am ] |

| Post subject: | |

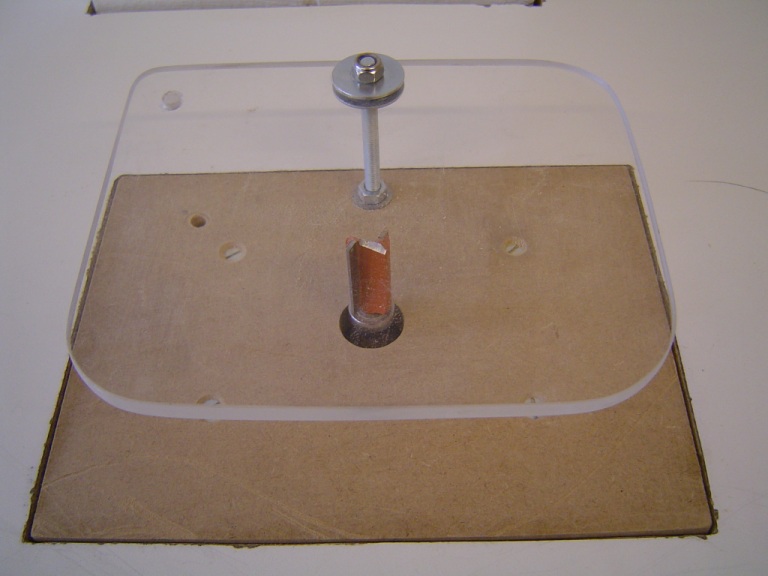

To follow up on what Bruce said I made one side 3/4" thick using a drum sander on the drill press to perfect the pattern. Starting with 60 grit and progressing to 120 grit. then I drilled (3) .375 dia holes thru. and match drilled the rest of the rough cut pieces to this pattern. Using .380 steel dowels I attached one rough cut side at a time to my perfected side and routed to shape on my router table using a 3 flut 1/2" x 1 1/2" tall pattern bit. Indexing the pilot bearing of the middle of the perfected profile. Once the routing was complete I used the same (3) pin holes and wood dowles to index the 3 pieces per side toagther during laminating glue up. Then I figured out I had better things to do with my time and have since bought my molds from John Hall    |

|

| Author: | L. Presnall [ Tue Apr 11, 2006 5:17 am ] |

| Post subject: | |

Exactly Michael! I made my first few molds just like you with the exception of my dowels were wood...now, I just buy John's! They're pretty and I got the #1 OLF SJ one...a hundred years from now, it'll be pure gold on EBay!

|

|

| Author: | Wayne Clark [ Tue Apr 11, 2006 5:21 am ] |

| Post subject: | |

I built one for a dread style, and it works just fine. I started with a hardboard pattern that I cut with a coping saw and cleaned up with sandpaper by hand. I used a jig saw to cut the plywood to within 1/8 inch of the line, bolted the wood to my hardboard pattern and used a pattern bit to trim everything even with the pattern. I can vouch for John Halls molds. I also bought the OLF SJ mold from John about a month ago. His is much nicer than mine! Very professionally done. I will go back to him to get a mold for an OM soon. |

|

| Author: | Evan Heisler [ Tue Apr 11, 2006 5:29 am ] |

| Post subject: | |

Is there any problem with constructing a mold from MDF? Probably 2-3 pieces of 3/4"? I suppose its easy enough to just go get some ply wood, but I have all this MDF on hand. I suppose it could have a little give to it? |

|

| Author: | Michael Dale Payne [ Tue Apr 11, 2006 5:37 am ] |

| Post subject: | |

No but seal the cut edges when done with shellac |

|

| Author: | Michael Dale Payne [ Tue Apr 11, 2006 5:39 am ] |

| Post subject: | |

I only used steel during the routing for pres fit and they were much longer so they were easy to pull with vise-grips |

|

| Author: | Colby Horton [ Tue Apr 11, 2006 6:22 am ] |

| Post subject: | |

Thanks for the help guys. I don't guess I'll be using the sanding method anyway. It sounds like it would be better to use the router table method. Right now I'm working on my 12th guitar. I built almost all my guitars free stand assembly method. I have now decided to take the plunge and build some molds. It should make life a lot easier. |

|

| Author: | JJ Donohue [ Tue Apr 11, 2006 6:28 am ] |

| Post subject: | |

Ditto on John Halls molds...it saves me time for building. |

|

| Author: | L. Presnall [ Tue Apr 11, 2006 7:35 am ] |

| Post subject: | |

Dang Todd, those are nice!  For anyone wanting to use latch clamps similar to John Hall's here's a cost effective link: For anyone wanting to use latch clamps similar to John Hall's here's a cost effective link:

Latch Clamps |

|

| Author: | Bruce Dickey [ Tue Apr 11, 2006 8:15 am ] |

| Post subject: | |

Colby, Tippersville, where exactly is that? Might make a nice road trip some time? Twelve, how about some pics? I don't think I have a file started on a Horton Guitar maker? Are you using radius dishes then? IF you aren't using molds it made me wonder? I bought my dishes, because Dave was practically doing it for fun. Some day I might even tool up and make one of those just to say I did it. |

|

| Author: | Serge Poirier [ Tue Apr 11, 2006 8:39 am ] |

| Post subject: | |

Awesome molds Todd! |

|

| Author: | L. Presnall [ Tue Apr 11, 2006 9:45 am ] |

| Post subject: | |

Serge, do you realize you're 2 posts away from 2000? |

|

| Author: | A Peebels [ Tue Apr 11, 2006 9:54 am ] |

| Post subject: | |

I have used both MDF, and ply for my molds. Both work well, but the MDF is much heavier. Al |

|

| Author: | Dave Rector [ Tue Apr 11, 2006 10:22 am ] |

| Post subject: | |

[QUOTE=L. Presnall] Serge, do you realize you're 2 posts away from 2000? [/QUOTE] Larry, I think that would be 102 away. Still, Serge has to be the fastest in the history of the OLF to reach 2000 posts. And that includes around 40000 smiley's. Go Serge!  |

|

| Author: | Rossy [ Tue Apr 11, 2006 12:45 pm ] |

| Post subject: | |

Colin, Do you have a picture of that bit for routing? Thanks. Ross |

|

| Author: | Serge Poirier [ Tue Apr 11, 2006 2:11 pm ] |

| Post subject: | |

Larry, 43 to go for 1000 posts, Keep on goin' bud, you might catch up with me if you post all day and all night for about a week or 2 but remember that i'm a trained professional when it comes to smileys!        |

|

| Author: | Colin S [ Tue Apr 11, 2006 8:21 pm ] |

| Post subject: | |

I use a CMT bit with a bottom bearing for use in my built in router table. The bit with the top bearing would be for use with a hand held router. It takes no more than an hour to make a router table and like Bruce I can't overstate how handy it is.

This one is 1 1/4" x 5/8" Colin |

|

| Author: | Serge Poirier [ Tue Apr 11, 2006 10:31 pm ] |

| Post subject: | |

Great thread guys, cool ideas here, thanks! Serge |

|

| Page 1 of 2 | All times are UTC - 5 hours |

| Powered by phpBB® Forum Software © phpBB Group http://www.phpbb.com/ |

|