OK...I'm getting the nerve up here to rout for the binding after stalling around for a few weeks (first time). I have a binding jig that I got from John Hall and it's hooked up to a PC 7310 laminate router. I'm using the BB router bit set from Stew-Mac.

What I'm not sure of is:

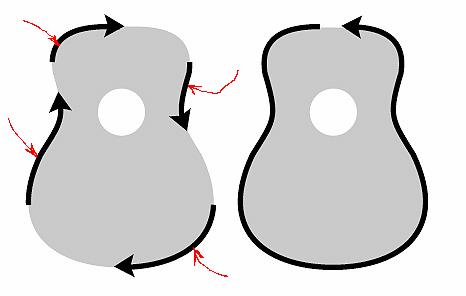

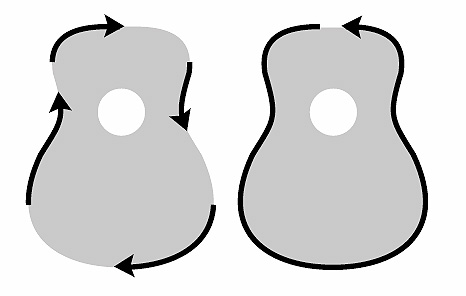

1. In what direction do you rotate the guitar body while the routers cutting? I'm trying to recall what everyone here has said, and clockwise comes to mind?

2. And...Which do you cut first the top purfling, then the binding, or vice-versa, or does it matter?

The binding is flame maple and the top purfling is going to be a 5-ply blk/wht/...plastic.

Setup:

, I cut my bindings first, but I use a trimmer with a guide bearing so can adjust the height of the bearing.

, I cut my bindings first, but I use a trimmer with a guide bearing so can adjust the height of the bearing.