just a few pics of my dads wood shop

maybe you could use these as far as placement of things

(wheres jimbo?)

| Official Luthiers Forum! http://w-ww.luthiersforum.com/forum/ |

|

| Show me your shops! Pics & tips wanted. http://w-ww.luthiersforum.com/forum/viewtopic.php?f=10102&t=6978 |

Page 1 of 2 |

| Author: | Mattia Valente [ Sun Jun 04, 2006 1:55 am ] |

| Post subject: | |

Right, so the house has been bought, keys are in my posession, the shop's cleared out save for some white latex paint (handy, since I wanted to paint the walls, possibly the ceiling) and two shelves. Have an appointment with the 'handyman' dude on Tuesday (don't have the time or the plumbing/electrical skills to remodel the kitchen as needed m'self, though we'll be taking on the painting/redecorating and I'll be helping lay the floor), which will be a good opportunity to measure up the shop properly, draw the plans, and start doing layout. So, basically, I'm looking for ideas and inspiration. And the smaller the shop, the better, since this is a pretty small space (as in, it'll fit the bandsaw, a bench on the opposite wall with some space between them, but that's it. I *think* it's about 8' x 6', maybe a touch more). I've got several ideas bouncing around in my own head, but more are always appreciated, particularly with regard to wood storage (boards, not the sets), tool storage, etc. Space is at a premium, so I gotta make do. The shed (that's what it is, really) is rectangular, brick/cement construction, flat wood roof with waterproofing (new, checked, intact, no humidity anywhere) with a single door (with glass) in right-hand the corner of one of the long sides (walk in, shop space is all to the left), no windows. Plans/ideas so far: - Paint walls/ceiling white, increase reflectance - install 2-3 dual fuorescent tubes (one warm, one bright per pair) for lighting, smaller worklights for details - Dust collector/small cyclone in one corner. Bulky, but I don't want to compromise on respiratory safety. Probably along same wall as bandsaw. - Bandsaw along the longer wall with the door in it (rectangular space), bolted to a pair of beams to raise the table and stabilize the entire thing. Mobility not an issue. Possibly add 'outfeed' table/worksurface at same height on other side. - Worksurface along entire other wall, 2' deep, an extension accessible from all sides to be added if space permits. Probably 'removable'. Probably around the 40-42" mark in height, MDF/Melamine worktop (cheap), bolted to the wall, a few legs (pine or birch) to provide framework for sub-bench shelving/storage, and a bit of stability to the front edge. A metalworking vise or two as well - I'm making a thickness sander, shooting for a compact one that I can slide away under the bench right across from the door when it's not in use. Or just slide in next to the bench, so I can use the drum to sand things like bridge wings, etc when I don't need the outfeed length. - Bolted plywood 'go bar deck' platform in one croner. Maybe extend deck/shelf along length to add wood storage. Wood storage likely also above bandsaw, if feasible. Or rather below the bench? - Possibly turn part of the work surface into a downdraft table with a central router mount (Table routing; I build electrics as well, after all). Alternately, homemeade pin router setup, although stability seems like an issue. These are just sort of brainstorming ideas at the moment, and I've also got tool storage to worry about, although I have a moderately sparse collection: handful of chisels (half a dozen, may double), handful of planes (6 bench/jointer, 1 block), a few japanese saws, rasps, files, that sort of things, a tabletop drill press (may be replaced in future), 3 routers (Bosch plunge, PC 690, PC310), jigsaw, portable drill, angle grinder, orbital sander. That's really about it, and I don't really feel like I'll be needing/wanting an order of magnitude more of these things, although more chisels and planes are likely to be added. So, y'all got thoughts or comments so far? Things I definitely should or shouldn't do? Pictures of (small) shops that I may freely raid for ideas regarding organization, storage, etc? |

|

| Author: | MATTRIX72 [ Sun Jun 04, 2006 2:19 am ] |

| Post subject: | |

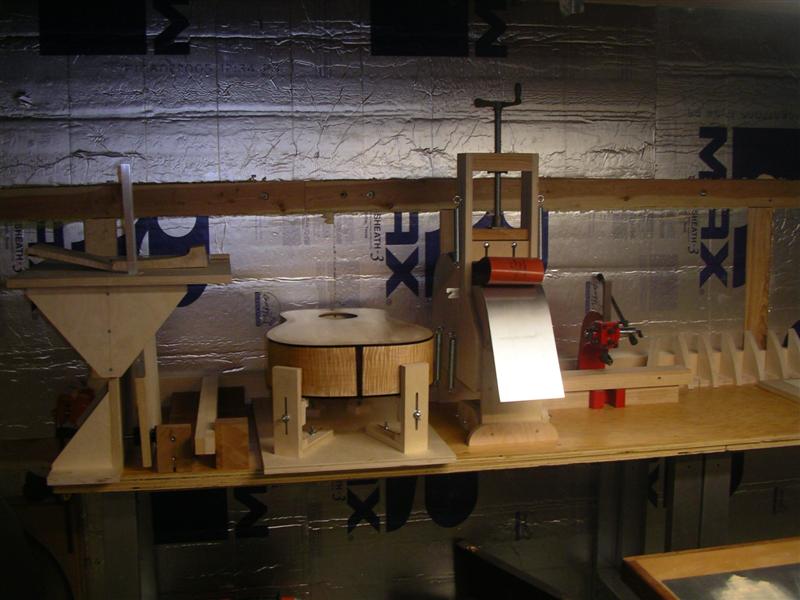

just a few pics of my dads wood shop

maybe you could use these as far as placement of things (wheres jimbo?) |

|

| Author: | Mario [ Sun Jun 04, 2006 2:34 am ] |

| Post subject: | |

Yikes! I'd get bummed out in that shop. Needs to be brighter, friendlier, more open. Needs paint. explains the bottle in every shot <g> Mattia, my shop's not small, but go take my tour(construction pages...) for ideas on layout and placement, lighting, etc... Definately paint the walls, and here's a tip from my lady friend who mixed my paint: have the pait person mix in some true blue into the semi gloss white. This results ina s"super white" paint that is very bright and eye friendly, and not at all tiring. And the semi-gloss adds light reflectance while being easier to wash and clean. Satins and mat paints actually hold dust... |

|

| Author: | Michael McBroom [ Sun Jun 04, 2006 3:19 am ] |

| Post subject: | |

Mattia, I thought I was working out of a small shop -- 9ft x 14ft. But 8x6 is downright tiny. First question -- will it be possible at all for you to add an exterior closet or similar to your shop? If so, I'd think about locating your dust collector to this addition. You can run a hose or pipe through the wall. Here are a couple of images of my workspaces. Please try to overlook the mess. I've been busy and it's been a couple weeks since I've done any tidying out here.

The first one is a three-shot panorama of the inside of my shop. It's so small, I can't even stand outside the door and get a complete shot of everything. I have relegated all of my dust-making tools to my covered patio. The only one that has a dedicated collection system is my drum sander -- a Rigid shop-vac located under the sander's table. My shop is wide enough (9ft) where I was able to build two benches, one on each long wall. I have built some shelving below the benches and I store a lot of other stuff under them as well. Almost every square inch of my walls is dedicated to shelves or tool racks. Build as many shelves as you can fit into your shop. They'll get used, believe me. I also built a table on locking casters -- can't see it -- it's buried under stuff at the left of the image (look for the neck blanks). When I first began building guitars, I used it a lot, and found the ability to roll it around the shop (for use or for moving it out of the way) very useful. I located my Parrot vise on the outside corner of the bench on the right (not visible in the photo), which maximizes its effectiveness when clamping long things like necks or even guitars in progress. One of these days, I'm gonna get my garage organized, and I'll move the lathe out there. I could really use the three feet of bench space it's currently occupying. Also, if you look closely just behind the light colored chair, you'll see a slab of Corian that was a sink cutout from somebody's kitchen remodeling job, laying on the workbench. I use this a lot because there are many times I need a very flat surface. I can highly recommend picking up something like this. If you can find a sink cutout, the best part of it is that it is usually free. The remodelers around here just throw them away. You'll also note the two round adjustable lamps. These are the ones with the fluorescents and magnifiers. Even though lighting is good in my shop, there are times that the added light that these provide is essential. Nice thing about them is that they are easily moved. I also have four outlet strips attached to the bench risers, and all get used. Next question: how tall is your shop's ceiling? If it is low, like mine is, then rather than building a dedicated gobar deck assy, you can do like I do, and set the radius dish on your workbench, then brace the gobars off the ceiling. That'll save you approximately four square feet of space. It's a lot easier to find the space to store a couple of radius dishes and the gobars than it is, in a small shop, to locate a gobar deck assembly. If it has a higher ceiling, you can still build a "drop-ceiling" extension over where the gobar deck will be located. This extension can double as a wide shelf or maybe even a set of shelves, too. Speaking of which -- don't forget about using your ceiling as a storage area. You can build shelves all along the ceiling for storing tonewood, binding, purfling, and other long items. Best, Michael |

|

| Author: | SimonF [ Sun Jun 04, 2006 3:27 am ] |

| Post subject: | |

Mattia, That is a small space to work around...but mine isn't a whole lot bigger. Here's a link to my workshop. http://www.fayguitars.com/guitars/workshop.html Good luck friend, Simon |

|

| Author: | Mattia Valente [ Sun Jun 04, 2006 3:34 am ] |

| Post subject: | |

Mario: thanks for the tips, I'll go snoop around. Yeah, it's tiny, but it's mine, and a major space upgrade from what I've got now! A lot of the gluing/detailing/etc. will be done indoors, different 'shop' area; I plan on doing the Go-bar like you described, pretty much; ceilings aren't that tall, maybe 8' or so, maybe 10', but I'll answer exact dimension questions when I've gone and measured the darn thing. Re: dust collector, I'm not sure I'll be able to do an outdoors collector, but I'll look into it. I suspect I'll keep doing quite a bit of work outdoors using my trusty workmate with extended table setup that's served me so well, weather permitting, but at least I'll have indoor control. Thankfully, humidity doesn't swing like crazy here. |

|

| Author: | Joe Beaver [ Sun Jun 04, 2006 3:35 am ] |

| Post subject: | |

Matt That is one great looking shop. You have so many great tools, band saw, drill press, sanders and of course the one I always find in my hands, Jim Beam

|

|

| Author: | Arnt Rian [ Sun Jun 04, 2006 4:32 am ] |

| Post subject: | |

First of all, congrats on the new aquisition Mattia! First you should make a list of every tool, clamp, wood shelf EVERYTHING that you plan to put in that shop. Measure your band saw and dust collector and other large items and start putting everything down own paper (or your favorite cad program, paper cut-outs of tools and benches, scale model, whatever) to see how, or IF everything fits together. Then: Kill your darlings! If that drum sander (or whatever) is just too large for the room it will have to wait for the next shop. I would hate to have to trip over that sander ever time I turned around! With a shop that small I would rely on hand tools for the most part. Here is an old picture of my main work / hand tool area:  |

|

| Author: | charliewood [ Sun Jun 04, 2006 5:41 am ] |

| Post subject: | |

I can sympathise about the small shop, but man I thought I had it rough in an 11x13 or so shop, holy crow your gonna have to do some serious space economizing friend. I have tried to incorporate 2 stations into one whenever possible - for example my gobar deck lifts out of the bench to reveal a pipe clamp clamping station, and the drillpress and table saw are both rollaways, and so will the bandsaw be once I get around to it - this is so I can get them ot into the solarium, or out on the deck when I need extra space. Its a bit harder to organize space for someone in a wheelchair, cause you dont have the height or reach of an upright person, So Im needing to take this into account as well in all my designs. nevertheless I am planning lots of verticle space use - the perfboard is a real good idea, but I am in the process of making shelving units as well, also the closet in the room Im using is also converted to contain 4 levels of shelving in them for solvents and knick knacks Im not using regularily. I have 2 6'x2' benches, which Im upgrading right now, also Im trying to provide space for storing body molds, bending gear, etc. Its been an uphill battle but Im gaining ground - I find a good mental strategy to use is no matter what stage you are at in organising your shop............... tell yourself and others that your almost done,  LOL LOL

PS Im almost there guys! Cheers Charliewood |

|

| Author: | Michael Shaw [ Sun Jun 04, 2006 7:25 am ] |

| Post subject: | |

Who knew Jim Beam had so many use in the shop. |

|

| Author: | DaleH [ Sun Jun 04, 2006 8:00 am ] |

| Post subject: | |

Yea I thought my shop was small at 8 X 12. I built it inside my garage, the home owners association wouldn't let be build anything of any decent size in my back yard. This setup still leaves my tablesaw,bandsaw & my thickness sander outside the shop in the garage itself.

|

|

| Author: | RichB [ Sun Jun 04, 2006 8:41 am ] |

| Post subject: | |

Mattia, I found this planner at the Grizzily site. Maybe you can use it to plan out where you need to fit in certain tools & things. I also work in a relatively small area (10' X 15'), so I chose somewhat smaller power tools, so I could cram what I needed in there. I also have a skylight for added daylight. I don't like flourescent lighting, so I hooked-up a bunch of halogens, although it gets a little hot in there when they're all on...but I can isolate them if need be. http://www.grizzly.com/workshopplanner.aspx I bought a cheapo Pergo-like flooring at Home Depot, and installed it in a few hours. The cold cement was way too cold, so it was a cost efficient move for me. The only downside to it is that you have to be careful not to drop anything too heavy on it. Work benches on 3 walls, and a take-down table if I need a bit more room to move. Underneath the benches allow me storage area. Shelves work nicely for whatever. A couple of cabinets for even more storage, a tool cabinet, and a compact refrigerator. I like wooden wine crates for odds & ends...

I have since added a shelf for a wood stash...

Also new is a guitar holder, that was on Sylvan Wells' site, that comes in handy: http://www.wellsguitars.com/Articles/Guitar_Holder.htm The irony of my small shop is that, on the other side of those french doors is a big garage, that is chuck full of my wifes accumulated junk, that just sits there and does nothing...  |

|

| Author: | Dave Anderson [ Sun Jun 04, 2006 9:50 am ] |

| Post subject: | |

Mattia, My shop is kind of split into two areas.It's half in my garage and half in a small room.The problem I have is they are at separate ends of the house so I'm walking back and forth. We don't have basements here in Florida. I am considering building an add on next to the garage.

I use a nearby closet for storage

The garage

|

|

| Author: | Rod True [ Sun Jun 04, 2006 11:27 am ] |

| Post subject: | |

LOFT, LOFT, LOFT, makes for lots of wood storage, and jigs as well.

And use the underside of the loft as the top of the go-bar deck

That's my two bits |

|

| Author: | D.L.Huskey [ Sun Jun 04, 2006 12:02 pm ] |

| Post subject: | |

Mattia, I saw this revolving work station in a publication called "The Complete Small Shop" that I thought would be a space saving item. I haven't built one yet, but will when I get some of my other projects caught up. Good luck on getting your New Shop set up. I know you are going to enjoy it no matter the size. |

|

| Author: | burbank [ Sun Jun 04, 2006 3:07 pm ] |

| Post subject: | |

D.L. that's a great way to make use of a corner. I saw a variation that had the rotating part set flush into the top surfaces the two intersecting workbenches. A big spinning inlay!

Mattia, Here's my machine corner in a slightly oversized one-car garage, 9 ft by 18 ft. I stay pretty much out of the last 7 feet or so of the length, for the kids' bikes, scooters, and such, so it's more like 9 x 11. Rather than scoot the DC around to each machine, I stuck it in the corner, which is normally pretty awkward to use well. It stays put, as does the DP, which is bolted down for safety reasons. The TS is closest to the DC to keep the DC hose run short, as it produces the most dust, until I get my thickness sander built, that is. The TS is on a roller base, since I sometimes have to move it to cut larger stock. The BS also rolls; it's moved out from behind the TS rail for each use. It's light and moves easily. The thickness sander is going to be on wheels and live under the DP table. Don't forget to put in more power than you think you'll ever need. It adds up quickly. Exciting time for you, eh? Have fun!

|

|

| Author: | Mattia Valente [ Mon Jun 05, 2006 2:33 am ] |

| Post subject: | |

Wow guys, great collection of pics! I get to go measure everything up properly tomorrow, so I'll come back with dimensions and stuff to start sketching out properly. In the meantime, thanks for all the inspirational pictures! |

|

| Author: | Serge Poirier [ Mon Jun 05, 2006 4:08 am ] |

| Post subject: | |

Hi Mattia, an old futton base can make awesome upper storage for molds and other jigs, like i did here. My shop is 12' x 21' You might want to consider putting your workbench on wheels like i did so you can work outside in the sunny days! Serge |

|

| Author: | Mark Tripp [ Mon Jun 05, 2006 5:32 am ] |

| Post subject: | |

Okie Doky - Here's mine - In a basement with very little natural light, but it works! Tablesaw and Jointer:

Radius Jig and Spindle Sander:

Drill Press and a little bit O' wood:

Workbench:

Bandsaw and Drum Sander:

More workspace:

And more...

And still more workspace:

Mandolins:

-Mark |

|

| Author: | LanceK [ Mon Jun 05, 2006 5:44 am ] |

| Post subject: | |

12X20 is all the wife would give me of our basement.

|

|

| Author: | Serge Poirier [ Mon Jun 05, 2006 6:43 am ] |

| Post subject: | |

Hey Lance, same size as mine and Mark, you got the same kind of (drawer type) vise as i have, i love to see your shop pics folks it's always interesting to see how you all deal with space issues!

|

|

| Author: | npalen [ Mon Jun 05, 2006 8:06 am ] |

| Post subject: | |

Hesh I see the Festool vacumn and considering investing in one. Main reason being they talk about a built-in filter cleaning device. Can you fill us in on how this works if yours is so equipped? Thanks Nelson |

|

| Author: | Mattia Valente [ Tue Jun 06, 2006 6:48 pm ] |

| Post subject: | |

Tiny update: shop size is: 2 meters x 3.50 meters x about 2.50 (height; that's roughly 6.5' x 11.5' x 8'). I'm off to start drawing plans, and pore over all the pics. Thanks again! I'll keep y'all update with pictures/drawings when I start getting stuff done... |

|

| Page 1 of 2 | All times are UTC - 5 hours |

| Powered by phpBB® Forum Software © phpBB Group http://www.phpbb.com/ |

|