Here's a few pics.

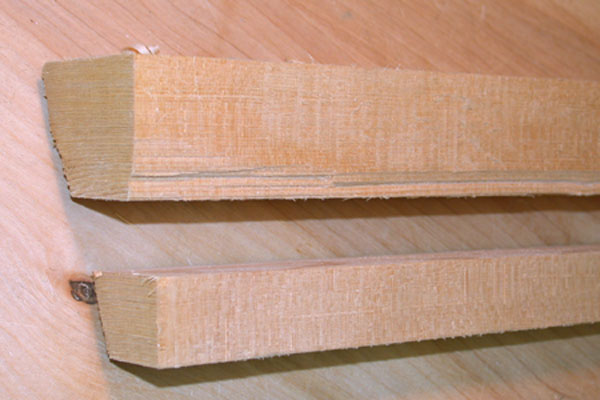

This is an extreme example of twist and runout in a billet.

It came to me looking pretty normal, until I split it.

Here, one piece is put back for illustration purposes.

Here's what I got on this split. Major runout.

I pretty much gave up on this billet altogether. Too much runout and twist. Not an inch of straight grain anywhere. If I'd just cut it up without splitting it to see what was there, the resulting braces might have been very weak.

Here's a good one.

The split surface is a perfect quarter, as evidence by the grain at the narrow part. The other lines to the left are from the tablesaw, which I used only to make the grain show up. I "developed" the split surface to use as a reference, with a plane and tablesaw, making it flat. From there, I split it vertically and make that surface flat. From there, I rip it on the tablesaw, ending up with something like these, which will be further ripped. No surprises here.

Oh, expect a fair amount of waste.