Steve,

I have a dremel that i used for binding channels on my first and it was such a nightmare that i put it away in it's case, did not even consider doing a rosette on no 2 with it, i bought the Porter Cable 7310 Lam trimmer and using this jig, it went much easier for the rosette and i'm using another jig for the binding channel.

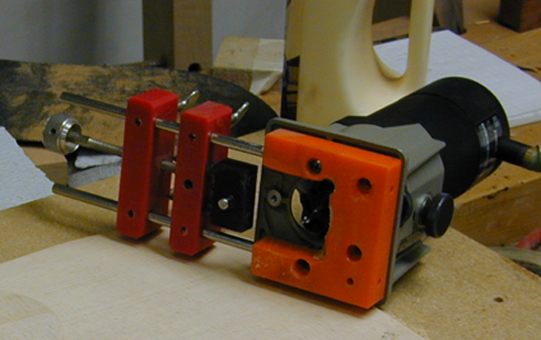

I do my rosette a la Mario's with a piece of plexiglass that i attach at the bottom of the dremel and decide where i want the diameters to be pivoting from, here's a pic

Is that BRW?

Is that BRW?