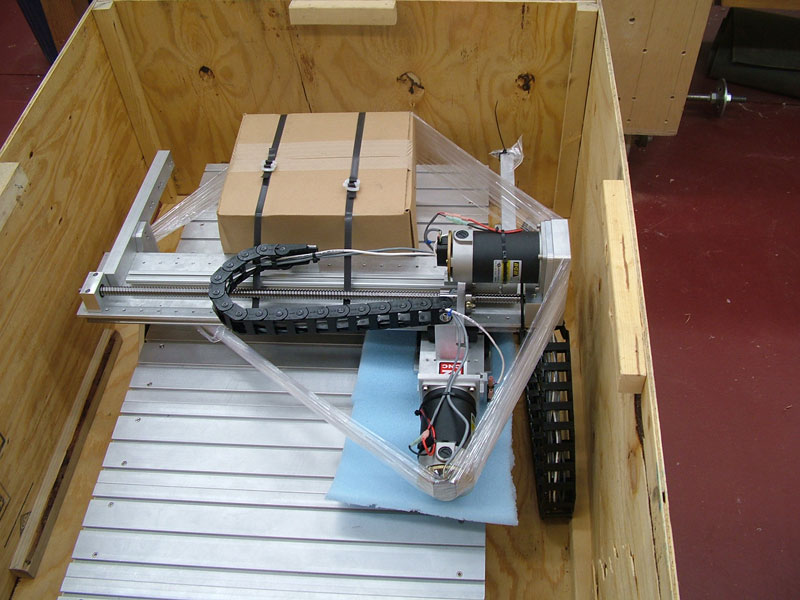

A Big Yellow truck showed up today and delivered this to the shop:

Hmmmmmmm wonder what it can be???

Let's get the drill and find out......

I can't believe it, it's FINALLY here!!!

Stupid box, where's that hammer....

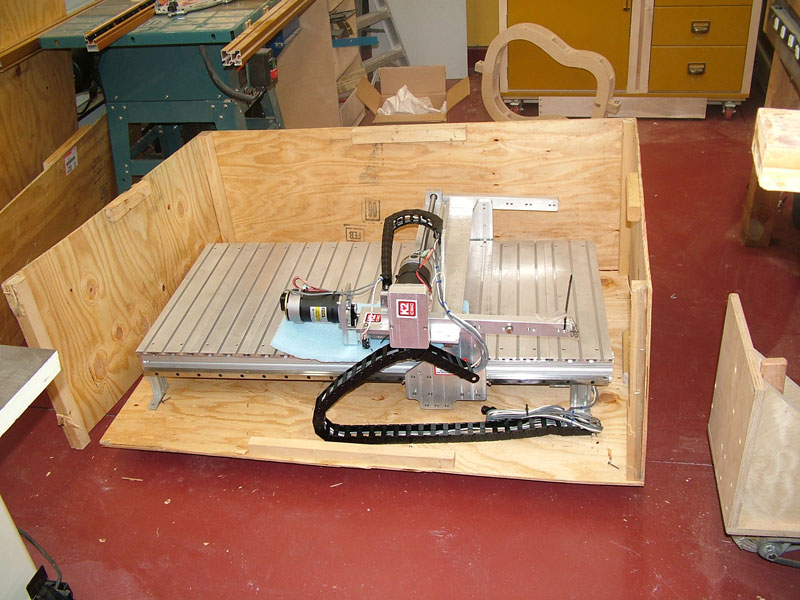

That's better, now we can load it onto the table and take stock....

That looks good, thank god I made the table a little bigger than I needed, this thing is heavy...

Here are all the parts:

There's no instructions but I pretty much know what needs to be done, so off I go... Didn't really run into any big problems, everything was tight. I just had to lift the Z-Axis bar and bolt it in and then bolt in the wire track, total time about 30 minutes.

So here's where this gets funny (well kind of)..... I start hooking up the controller for testing, I ask some questions and K2 is very responsive. I finally go to plug it into the Dell and guess what?? NO FLIPPIN PARALLEL PORT!!!

Dang Dell morons (sorry Dell lovers), they can't even put a standard IEEE parallel port on the flippin computer so I call a bunch of shops and finally find one that carries a high speed port that has all the right features, $23 bucks later and I'm ready to.

Here's what it looks like:

They have instructions but to be honest they are for people who have done this before so I'm a little lost but I putter through and finally I can run the one demo program and the machine works. I figured out how to set the Zero for X,Y and Z...

So now for the experienced around here I have a couple of questions.....

1. For the Z axis, should positive be down and negative be up? so for instance if I set it at Z0 (which is up against the limit switch) then should positive numbers make it go down??

2. Are there any good reference books or courses on doing machining with CNC? I'm really winging this, I'm pretty sure with some tweaking I can make flat jigs and do inlays but the more I know the better I can work with the machine.

3. I guess the same question about the Z Axis could apply to the X and Y but it seems obvious to me that positive would be away from the limit switches..

I'm overall very happy with the machine, my only real complaint is that for a newbie like me it's a little over-whelming, I'd love to see a good set of starter instructions written for people new to this. I told them that they would get more customers doing this so doing a little extra work for beginners would be a great help.

I have not hooked up the router just yet, I want to make sure I understand and can control the machine first, if I can make a drawing and not destroy the pencil then I'll be ready, little steps

. I also want to hook up a little control panel so I can kick on router, and dust collector from the keyboard. Not sure how to do that just yet but I'll figure out something. I also need to play with the quick change chuck I bought for the router, there's just so much to figure out on this, it's going to keep me busy for a while

. I also want to hook up a little control panel so I can kick on router, and dust collector from the keyboard. Not sure how to do that just yet but I'll figure out something. I also need to play with the quick change chuck I bought for the router, there's just so much to figure out on this, it's going to keep me busy for a while

They provide MachII for the controller software and once I figure it out I'm going to go up to MachIII as it has some nicer features. They do have scripting in this version so I'll do some things like add a home button to home the machine and little things like that. I spent a week in Seattle last week taking a Rhino Cad class at their headquarters, it was money well spent, now I just need to figure the machine end out and I'll be jommin mon!!!

I promised a bunch of people updates as I worked my way through this adventure so consider this the opening chapter, the $700 for the Rhino class was the best money I've spent in a while. I'm confident of my abilities in it now, Rhino-Cam... well that's another story

Cheers

-Paul-

If mach will do the touchpad then you just need to figure out how to wire it up to the controller. You'll need a touchpad block of aluminum that has been milled to an accurate thickness on the business end. Again I'm surprised somebody doesn't just offer that kit.

If mach will do the touchpad then you just need to figure out how to wire it up to the controller. You'll need a touchpad block of aluminum that has been milled to an accurate thickness on the business end. Again I'm surprised somebody doesn't just offer that kit.