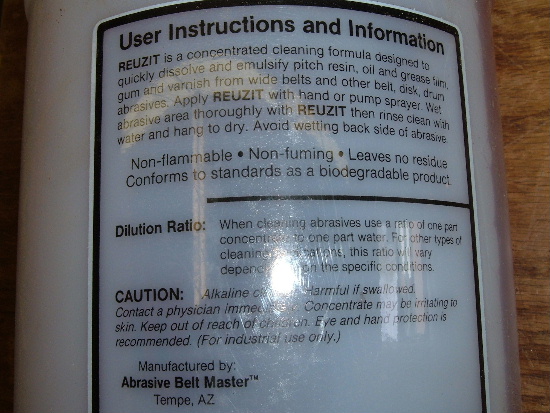

Check out this photo. I "think" it's of the model that is considered a little earlier than the 31-255X (meaning X5).

Anyway, this one is used and is relatively near me. Might could be had for a decent price. Some of the Delta reviews on Amazon indicate that the earlier models had some table gear issues that were aggravating. This supposedly was cleared up in later versions of the sander (again, the X5 model). The guy who has this is convinced it is the X5 model, and I don't think it is. (I'm willing to be wrong though)

Will one of you who had THIS model, get the model number off the machine for me? Also, have you had any issues with the table raising/lowering mechanism, or the table drive belt gears?

Thanks greatly. Buying a used tool scares me somewhat: no warranty, don't know how it's been treated, etc.