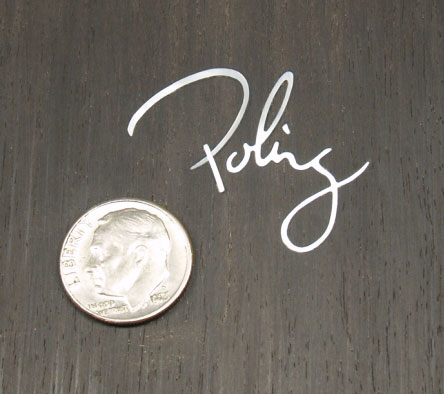

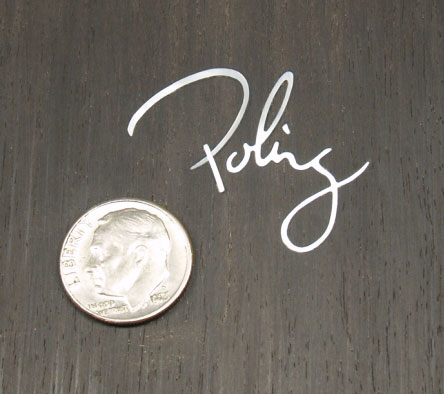

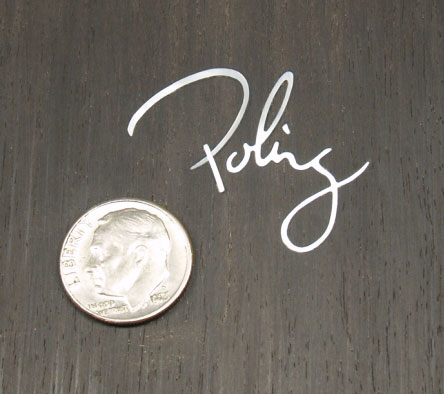

My new logo is super fragile and tiny tiny tiny.... I asked John if his machine would be capable of cutting these and corresponding pockets. Here is what he came up with.

Never in a million years could I do this with a jeweler's saw.

| Official Luthiers Forum! http://w-ww.luthiersforum.com/forum/ |

|

| John Watkins’ new trick http://w-ww.luthiersforum.com/forum/viewtopic.php?f=10102&t=8511 |

Page 1 of 2 |

| Author: | Brock Poling [ Mon Sep 18, 2006 9:47 am ] |

| Post subject: | |

My new logo is super fragile and tiny tiny tiny.... I asked John if his machine would be capable of cutting these and corresponding pockets. Here is what he came up with. Never in a million years could I do this with a jeweler's saw.

|

|

| Author: | Jim Watts [ Mon Sep 18, 2006 9:51 am ] |

| Post subject: | |

WOW! |

|

| Author: | CarltonM [ Mon Sep 18, 2006 9:56 am ] |

| Post subject: | |

That guy can stop on a, er, dime! That looks great, Brock! |

|

| Author: | Don Williams [ Mon Sep 18, 2006 9:58 am ] |

| Post subject: | |

Wow....now that's impressive. Hmmm.....oh John......!

|

|

| Author: | Bobc [ Mon Sep 18, 2006 10:46 am ] |

| Post subject: | |

Very nice Brock. |

|

| Author: | TonyKarol [ Mon Sep 18, 2006 10:49 am ] |

| Post subject: | |

I say thats cheating .. wait, I got a guy doing that for me !!!! Actually, hes making me routing templates for the recess so I can put my logo wherever I want to. very cool Brock, no other way really. |

|

| Author: | Steve Saville [ Mon Sep 18, 2006 10:51 am ] |

| Post subject: | |

That's nice. I'm going to have to do one too. |

|

| Author: | Evan Gluck [ Mon Sep 18, 2006 10:52 am ] |

| Post subject: | |

Obviously you need to raise your prices by $00.10

Evan |

|

| Author: | 1bordeaux [ Mon Sep 18, 2006 11:26 am ] |

| Post subject: | |

[QUOTE=Brock Poling] Never in a million years could I do this with a jeweler's saw.  [/QUOTE] [/QUOTE]

Why not?

Paul |

|

| Author: | Brock Poling [ Mon Sep 18, 2006 11:45 am ] |

| Post subject: | |

Oh sure.. I know *** YOU *** could do it, but I am not that handy with a jeweler's saw. I will stick to torches. :-) |

|

| Author: | JBreault [ Mon Sep 18, 2006 12:11 pm ] |

| Post subject: | |

I've just begun to take a jeweler's saw to pearl and couldn't dream of attempting that! That Watkins guy sure ishandy with his CNC.

|

|

| Author: | Serge Poirier [ Mon Sep 18, 2006 2:33 pm ] |

| Post subject: | |

Very impressive indeed, WOW ever tiny!

|

|

| Author: | Anthony Z [ Mon Sep 18, 2006 3:24 pm ] |

| Post subject: | |

Excellent Brock and nice work John. Brock when you posted pictures of your new logo I was thinking: (i)how would you be able to cut them so fine; or (ii) that'll be one monster headstock. It's gonna look sensational! |

|

| Author: | Billy T [ Mon Sep 18, 2006 5:56 pm ] |

| Post subject: | |

Huhm! I wonder how small this Watkins guy can go? Uh Oh! I think I gave somebody an idear! Sure looking good there Brock! There's like no filling or anything! Billy Dean Thomas |

|

| Author: | Arnt Rian [ Mon Sep 18, 2006 7:30 pm ] |

| Post subject: | |

It looks very nice, Brock. That coin is a dime, right? Those are so small, will you be able to see it?

I guess I'm lucky because my last name is short, and the way I write it the logo can be cut from two separate pieces of pearl (see the avatar to the left of this post). Still, both of those pieces are probably larger than your whole logo, never in a million years could I cut one as small and intricate as that. |

|

| Author: | John Watkins [ Tue Sep 19, 2006 12:00 am ] |

| Post subject: | |

Thanks, guys. I appreciate all the nice comments. "I wonder how small this Watkins guy can go?" Really, really, really small.

|

|

| Author: | npalen [ Tue Sep 19, 2006 12:06 am ] |

| Post subject: | |

John--I'm guessing 1/64" endmill for the cavity? Nice work! Nelson |

|

| Author: | John Watkins [ Tue Sep 19, 2006 12:37 am ] |

| Post subject: | |

...and for the pearl. Good eye, Nelson! |

|

| Author: | Scooter B [ Tue Sep 19, 2006 1:02 am ] |

| Post subject: | |

That is truely amazing and just a beautiful logo to boot. I think I would need reading glasses to see it in person! |

|

| Author: | L. Presnall [ Tue Sep 19, 2006 1:09 am ] |

| Post subject: | |

Hey, how do we know that's not a trick dime...say, the size of a Mayes neck building CD or something...?!!  Really, that's nice work on both your parts. John, could you make a routing template from a logo if a guy sent the cut pearl to you? Really, that's nice work on both your parts. John, could you make a routing template from a logo if a guy sent the cut pearl to you?

|

|

| Author: | John Watkins [ Tue Sep 19, 2006 4:50 am ] |

| Post subject: | |

Larry, that would be a tough one to do accurately. I think I would need something a little thicker for the trace probe. Also, I think you would have a lot of cutter breakage pushing those super small ones by hand. |

|

| Author: | L. Presnall [ Tue Sep 19, 2006 4:57 am ] |

| Post subject: | |

Okay, just thought I'd check...  How's the headstock template coming? How's the headstock template coming?

Larry |

|

| Author: | Michael Dale Payne [ Tue Sep 19, 2006 7:52 am ] |

| Post subject: | |

[QUOTE=L. Presnall] Hey, how do we know that's not a trick dime...say, the size of a Mayes neck building CD or something...?!!  Really, that's nice work on both your parts. John, could you make a routing template from a logo if a guy sent the cut pearl to you?[/QUOTE] Really, that's nice work on both your parts. John, could you make a routing template from a logo if a guy sent the cut pearl to you?[/QUOTE]

Larry are you planing on using a duplicator type routing fixture to do the routing with? If so have you tried friendly plastic. I have made several logo molds and full vine molds using friendly plastic. It works very well. It is a bit tough on the hands because it gets pretty hot when melted in hot water but I make small box frame twice or three times the logo thickness and big enough to give 1/4" clearance around the edges of the logo. Glue the logo upside down on a piece of scrap flat wood bigger or longer than the box frame. Heat the friendly plastic and fill the box with friendly plastic. Then press the logo into the friendly plastic till the wood that it is glued to is even with the edges of the box frame. Allow to cool and remove the logo straight up then remove the box from from around the friendly plastic. There you have a negative image of the logo to use as a routing guide for a duplicator. If the logo is a real delicate scrollwork coat the logo with Pam cooking spray just before pressing it into the hot friendly plastic and it will release easy. Then with hot water submerge the wood and glued logo to release the logo from the wood you glued it to. This also removes the cooking spray from the logo. I have actually made one of these then took it and chilled it a bit and sprayed it with Pam. Then use it to make a positive of my logo for routing the logo its self. Chilling the negative image friendly plastic mold was to keep the it from deforming when pressed into the hot friendly plastic. |

|

| Author: | Mike Collins [ Tue Sep 19, 2006 8:22 am ] |

| Post subject: | |

Simply beautiful! Mike Collins |

|

| Author: | L. Presnall [ Tue Sep 19, 2006 8:47 am ] |

| Post subject: | |

Michael, I've actually thought of using friendly plastic for this, and now you've given me the juice!!  I'm gonna try it when I get back out in the shop...(two more Ireland trips first I'm gonna try it when I get back out in the shop...(two more Ireland trips first  )...should be building again by Oct. 5...thanks for the shot in the arm! )...should be building again by Oct. 5...thanks for the shot in the arm!

|

|

| Page 1 of 2 | All times are UTC - 5 hours |

| Powered by phpBB® Forum Software © phpBB Group http://www.phpbb.com/ |

|