I'm slowly starting the planification of no.3. The top and back are joined. They are not down to thickness, but the sides are.

This will be a first for me. I've never worked with shell. I also want to try inlaying my headstock with a custom logo. (wish me luck!) Another first in the project is a florentine cutaway. I know, as Hesh once told me, I'm a glutton for punishment!

Now these quasi-blanks are a bit wide for my taste. I don't mind a wider rosette, but the side purfling has to be narrow...

I took a jewelers saw and cut one piece in half. I'm slowly 'jigging' up to sand and shape shell to profile.

Anyways, I can see why they say that inlaying shell can double the time for building a guitar!!!

I won't say how long it took me just to shape that 2" length! (last pic)

I won't say how long it took me just to shape that 2" length! (last pic)

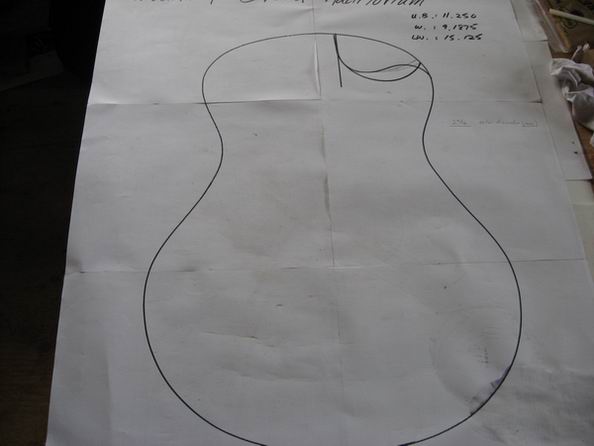

So here's the shape. Smaller than a dread. Grand auditoriumish???