I used regular titebond and those little clamps. I used a hot pipe to bend the bindings when the glue was dry.

| Official Luthiers Forum! http://w-ww.luthiersforum.com/forum/ |

|

| Side purfling question. http://w-ww.luthiersforum.com/forum/viewtopic.php?f=10102&t=8631 |

Page 1 of 1 |

| Author: | Dave Rector [ Wed Sep 27, 2006 6:49 am ] |

| Post subject: | |

I have always used the flexible ABS purfling like Martin sells for my side purfs. I am using the fiber/maple/fiber purfling on my latest build and have a question for those of you that laminate it to your bindings before bending. What methods do you use to glue this small purf to the bindings? I have considered tape, some kind of jig or fingers and CA but don't know what would be the easiest and most consistant. Any help would be appreciated. |

|

| Author: | Arnt Rian [ Wed Sep 27, 2006 6:55 am ] |

| Post subject: | |

Tape and CA for me, works OK but somewhat time consuming. I have seen jigs that wedge the purfling and binding together for gluing. |

|

| Author: | Michael Dale Payne [ Wed Sep 27, 2006 7:06 am ] |

| Post subject: | |

I don't glue mine together I find it easier to fit end graft miters if they are separate. I tape them to my bindings during bending but install them as separate components. |

|

| Author: | Wayne Clark [ Wed Sep 27, 2006 7:09 am ] |

| Post subject: | |

I used regular titebond and those little clamps. I used a hot pipe to bend the bindings when the glue was dry. |

|

| Author: | burbank [ Wed Sep 27, 2006 7:11 am ] |

| Post subject: | |

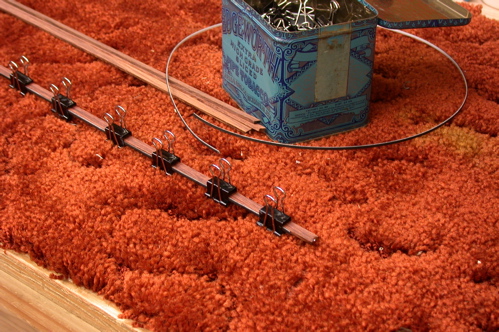

I've finished exactly one side purfling job. I tried tape as Arnt suggested, but the cleanup was very time-consuming. Then I tried this

and had much better luck. I lightly waxed the inside of the clips just in case I got some glue on them, then was careful to drip the CA only on the areas without the clips. I hit it with the accelerator, then took off the clips and dripped glue on the whole thing again. Worked great, little cleanup. |

|

| Author: | Dave Rector [ Wed Sep 27, 2006 7:36 am ] |

| Post subject: | |

Thanks guys, exactly the info I was looking for! Pat, I already have a bunch of the clips like in your pic. Maybe I'll give your method a go. Thanks! |

|

| Author: | Dennis Leahy [ Wed Sep 27, 2006 9:26 am ] |

| Post subject: | |

Dave, This may not be what you were asking, but if you make your own bindings, you can make them with the purfling strips already on. Let's say you want to make binding with a Black/White/Black purfling. Glue up a sandwich, using Titebond III: 3/16" x 3" solid binding wood of your choice 1/32" x 3" Black veneer or fiber 1/32" x 3" White veneer or fiber 1/32" x 3" Black veneer or fiber Use 3/4" x 3" MDF for gluing cauls. You may want to wet down the opposite side of the last veneer, to help prevent curling. (All the other veneer sheets are already wet on both sides.) Clamp with even pressure, and lots of it! (If your veneer is not flat, you may want to pretreat it with a glycerin-based veneer softener, and press flat.) When dry, joint/trim one edge, then with the veneers facing up, cut binding strips about .10" using a fine blade, and finally, sand to .080" Titebond III can withstand the temperatures needed to bend the binding strips. If you have the binding strips finished before you bend, you can even tape them to the edges of the sides, and do all the bending at once. (I'm just passing on tips from folks like Grant Goltz and Greg Nelson, but I did one set and this method does work.) Dennis |

|

| Author: | Dave Rector [ Wed Sep 27, 2006 9:49 am ] |

| Post subject: | |

Thanks for the info Dennis! This time I already have the koa binding and it is precut. Your method would be what I would do if I was making it from scratch. |

|

| Author: | Dave Rector [ Thu Sep 28, 2006 12:17 am ] |

| Post subject: | |

Thanks Todd! You wouldn't happen to have a pic or two of your tablesaw jig for precision binding would you? |

|

| Author: | rlabbe [ Thu Sep 28, 2006 2:43 am ] |

| Post subject: | |

I bought a UHMC cutting board at safeway for about 2 bucks, sliced two pieces off the end with my bandsaw. Clip one slice on to the rest of the board with 2 pony clamp. This is your fence. Put the binding/purfling sandwich against this. Take the other slice and press it against the sandwich, and pin in place with a couple more pony clamps. Hit with CA. Remove the pinned on slice, move the binding sandwich down to the unglued part, and repeat. 5 minutes and you are done. After awhile you may get some sticking with the UHMW. A bit of wax ends that problem. |

|

| Author: | Dave Rector [ Thu Sep 28, 2006 3:21 am ] |

| Post subject: | |

Thanks Roger! I have a bunch of that stuff that I bought from my local plastics guys. Sounds like an excellent way to get this done! |

|

| Page 1 of 1 | All times are UTC - 5 hours |

| Powered by phpBB® Forum Software © phpBB Group http://www.phpbb.com/ |

|