Hesh, that looks like a great way to do it, but check the Tools, jigs and techs section for yet one more way.

OR you can follow THIS LINK

| Official Luthiers Forum! http://w-ww.luthiersforum.com/forum/ |

|

| Making a Side Profile Template http://w-ww.luthiersforum.com/forum/viewtopic.php?f=10102&t=8994 |

Page 1 of 1 |

| Author: | Kim [ Tue Oct 24, 2006 11:47 pm ] |

| Post subject: | |

There ya go Hesh Right Here Cheers Kim |

|

| Author: | LanceK [ Wed Oct 25, 2006 12:08 am ] |

| Post subject: | |

Hesh, that looks like a great way to do it, but check the Tools, jigs and techs section for yet one more way. OR you can follow THIS LINK

|

|

| Author: | Dave Rector [ Wed Oct 25, 2006 2:39 am ] |

| Post subject: | |

Hesh, I used Colin's method on the dred I am currently building. It works flawlessly. Thanks again Colin! |

|

| Author: | Colin S [ Wed Oct 25, 2006 3:37 am ] |

| Post subject: | |

Hesh, turn the mould over, or the template material. Colin |

|

| Author: | JJ Donohue [ Wed Oct 25, 2006 3:49 am ] |

| Post subject: | |

Hesh...I essentially keep the top edge flat and only profile the back edge. it not only helps me to align it better in the Fox but there is such little sanding on the top later anyway. It's worked for me. |

|

| Author: | Dave Rector [ Wed Oct 25, 2006 3:58 am ] |

| Post subject: | |

I do what JJ said. |

|

| Author: | Kirt Myers [ Wed Oct 25, 2006 3:58 am ] |

| Post subject: | |

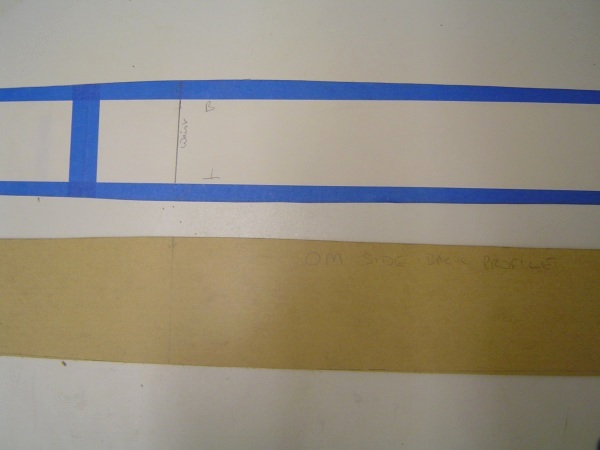

Hesh, I just made a template using Colins method about a week ago. It worked great. My top and back radii are different so I marked the back with the 16' dish. Transfered the tape to my pattern stock, then marked the top profile on another piece of tape using my 25' dish. When you transfer the profiled tape to your template make sure the tape is dead straight. Here's a couple shots.

I used a block of wood for a marking guide.

Set my head and tail depths.

Then cut along the marked lines.

I think JJ is right to just go flat on the top. I gives you a nice straight reference edge to work with when your bending. |

|

| Author: | Colin S [ Wed Oct 25, 2006 7:00 am ] |

| Post subject: | |

Hesh, like most of the others (as I said in Lance's thread) I only profile the back of the wood prior to bending, although I do trim the sides straight close to the final height of the sides, (so that I get some bindings from the waste). I then use a set square off that straight side to the waist on the back side to register it in the bender. I have a small 'V' nick in the slats where the waist goes and a mark on the side of the bender. When the end blocks are glued in, then I use my heavy paper profile of the sides, wrapped around, to mark the profile for the top which is then planed and sanded to final profile. So, I have two profiles made up, one from thin ply has just the back profile with the other edge straight and just larger than the overall width of the sides. The other is heavy paper and is the perfect profile of both back and top with the correct head and tail heights.

Colin |

|

| Author: | James Orr [ Wed Oct 25, 2006 9:41 am ] |

| Post subject: | |

I'm still not sure how it works. How do you account for the taper of the sides? For example, 4.5" to 3.5" tail to head (hypothetical numbers)? |

|

| Author: | James Orr [ Wed Oct 25, 2006 10:13 am ] |

| Post subject: | |

Never mind, I realized that you'll just draw this line and connect it from the tail height point to the head height point, whatever the heights are; the arch will not change. What if I don't want a straight taper? Could I break the line up into pieces once drawn and still just connect it from point to point to point? Example: break the line into point A to point B, then have point B to point C in the second line? Draw my heights for point A, B, and C, then connect the tape segments accordingly? I'll try to draw a graphic. (Edit: I'm adding a drawing)  |

|

| Author: | James Orr [ Wed Oct 25, 2006 10:32 am ] |

| Post subject: | |

Good point, hesh. This does seem very very simple now that I grasp what's going on. |

|

| Author: | Richard_N [ Thu Oct 26, 2006 12:53 am ] |

| Post subject: | |

Very Interesting thread. One thing that I dont quite understand is that in my books they say you make the back flat to the widest point of the lower bout and then curve the sides to the headblock. As far as I can see everyone here sands with a radius dish between the headbock and tail block. Does that mean that by using the different hight endblocks and a radius dish centred in the middle of the lower bout you create the same profile (ie flat to the middle of the lower bout and then a gentle curve to the headblock) ? Or is there something I'm missing out on here ? |

|

| Author: | Richard_N [ Thu Oct 26, 2006 1:46 am ] |

| Post subject: | |

Hesh I'm using Cumpiano and Kinkeads books and Robert O'Briens DVD (prompted by recomendations here) . Prompted by what I've seen here and in the DVD I'm currently making The radius dishes ( 30' and 15' as in the DVD ). I can see how sanding with the dish will mean that the back fits better to the sides and also how the sides are going to be curved ( front and back) for the reason you mentioned but am not sure as to if I still need to plane the back profile to the peak( using for example the template in Kinkeads book or a sanding board as in Cumpianos book ) Hopefully as you say once I've got the dishes finished I will be able to my exterior mould in the dish and it will come clear. If you can help shed a bit of light I'd apreciate it. I was thinking that Colins method would also be usefull for marking out where the depth reducing inserts go on a "kinkead style " mould if using a radius dish on the sides. Thanks |

|

| Author: | Mike Mahar [ Thu Oct 26, 2006 2:10 am ] |

| Post subject: | |

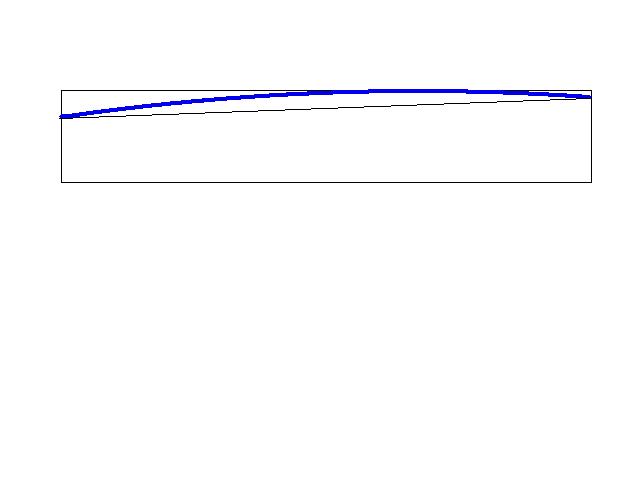

Making an arch that starts high at the tail of the guitar and goes low at the heal is visually almost identical to the flat/slope method. Look at the drawing. From the back to about the widest part of the lower bout there is very little change in height. Most of the apparent difference comes after that. Fans of baseball will note that this is the same reason that curve balls appear to head straight at the batter and then suddenly break as they get near the plate.  |

|

| Author: | Richard_N [ Thu Oct 26, 2006 7:17 am ] |

| Post subject: | |

Thanks Mike. Thats what I was kind of thinking and your diagram makes it very clear. Wasn't sure if thats what you're all doing or if I was missing something. I apologise for hijacking your thread like this Hesh ! |

|

| Author: | Colin S [ Thu Oct 26, 2006 8:50 am ] |

| Post subject: | |

Hesh, see I am right sometimes! (Don't tell my wife) Glad it worked out for you. Now a nice bit of clear French Polish on the top and you'll have a great guitar  . .

Colin |

|

| Author: | Serge Poirier [ Thu Oct 26, 2006 11:47 pm ] |

| Post subject: | |

I'll be trying that out very soon too, thanks again Colin! Hesh, it looks great bro! |

|

| Page 1 of 1 | All times are UTC - 5 hours |

| Powered by phpBB® Forum Software © phpBB Group http://www.phpbb.com/ |

|