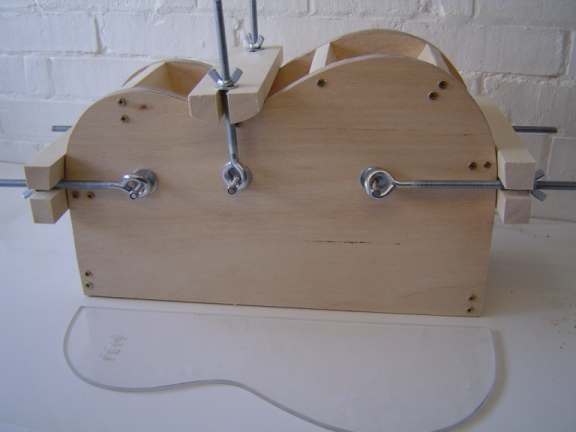

Lance...I make a waist mark on the wood, paper and slat and line that mark with the slot on the Fox bender before turning the screw. In addition, the flat side (top) is lined evenly with one side of the bending form. When doing the 2nd side, the flat portion is lined evenly with the opposite side of the form.

This requires lots of concentration and care before starting the bend...don't ask me how I know