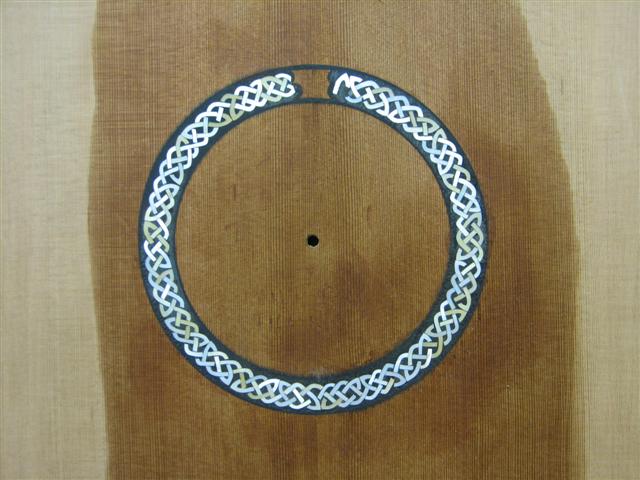

Well, I'm not very happy at all with the way this Celtic rosette is turning out.

I certainly don't like the epoxy. It's not getting hard enough. I've let it set now for 4 days, shop temperature is 22*C (72*F) but I can still quite easily indent my thumb nail into it. I would think that it should be harder than that. When I mixed it, I was careful to mix 1:1 as the container stated. I'm using the G1 epoxy from Lee Valley and it says to use it at or above 20*C so I should be good.

Anyway, I've been working at leveling the rosette and the epoxy is curling up on me. If I sand it, it smears and leaves big holes. If I use a scraper, it gets to hot and pulls it up.

Needless to say, I'm very disappointed with the whole thing and really feel like throwing the top at the wall. I haven't done that yet, but getting closer.

To boot, since I've tried to level this thing out so much, I've sanded through some of the gold on the MOP and now it's a white and gold MOP rosette instead of all gold

.

.

Anyway here it is, in all it's ugliness. I think I will call up Andy and get another one, route this one out, inlay it properly and fill it all with ebony dust and CA.

And here is the spalted maple rosette. I'm 99% happy with that one.

I also started to bend the sides for the curly maple guitar. It cracked on a figure line in the upper bout. I did a very light spritz (the wood sucked up the water really fast) wrapped it in foil, sandwiched like so, ss wood blanket ss got it up to 275*F (could be my thermometer is bad though) and there was steam coming off the sides and it almost smelt like burning wood, so I did the waist first to about 75%, than the upper bout, than the lower bout than the rest of the waist, than I noticed a nice sharp break at the upper bout. #%$^&*$#

Time to build a new bender and get a good thermometer and maybe take some side bending lessons.

I feel like giving up

I'm going to go eat and drink now.

. I once spent for ever binding up a very expensive composite game fishing rod blank with the best components I could afford. Hours and hours of careful meticulous eye straining work, interlocking pattens of different coloured cottons upon a setup that had been sooo carefully planned out.

. I once spent for ever binding up a very expensive composite game fishing rod blank with the best components I could afford. Hours and hours of careful meticulous eye straining work, interlocking pattens of different coloured cottons upon a setup that had been sooo carefully planned out.

Never mind, I guess that is for CA.

Never mind, I guess that is for CA.