With the amount of tearout you appear to have I would not recommend

filling it at all. Epoxy fill would require using epoxy to glue the bridge as

well, and would give you relatively low heat resistance, and less creep

resistance than hide glue. Using hide glue and sawdust may give peace of

mind that there isn't a gap, but won't have much to offer structurally. If

the pieces are large enough to cleanly remove from the bridge I feel the

best method is to glue them back to the top. In your case I don't know

that would be necessary.

When I glue bridges I don't remove the finish all the way to the edge. This

can be difficult to do cleanly, but my main concern is finish cracking when

pressed against the sides of the bridge. This can happen with humidity

fluctuations or more often with even minor creeping. It doesn't happen

often, and if it is properly glued it should never creep in an ideal world,

but if you want it to look good in 20 years you can't always count on ideal

conditions through that time. Again, it's not too common a problem, but I

do see it occasionally.

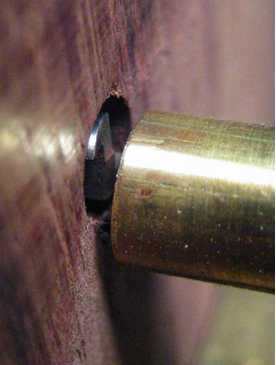

I actually recess a small lip around the edge of the bridge. This way you

can have a solid wood to wood contact, with the edge of the bridge kind

of floating over the finish around the perimeter. The lip on the bridge

should be exactly or very slightly less then the ledge from the top/gluing

surface to the finish surface. This addresses the stress riser that Barry

mentioned while giving you a very clean look. I think I stole this technique

from Collings, but it's been so long that I don't remember.

|