Well, the process was posted on another forum, so I guess I'd share it with the rest of the family!

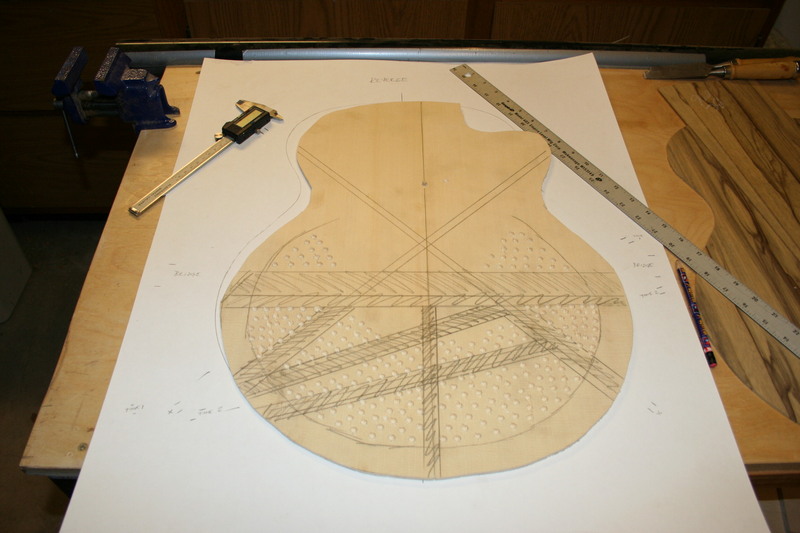

1. First I got the bottom top (bottom top??) Englemann Spruce cut and I marked exactly where the braces where going to be glued on.

.

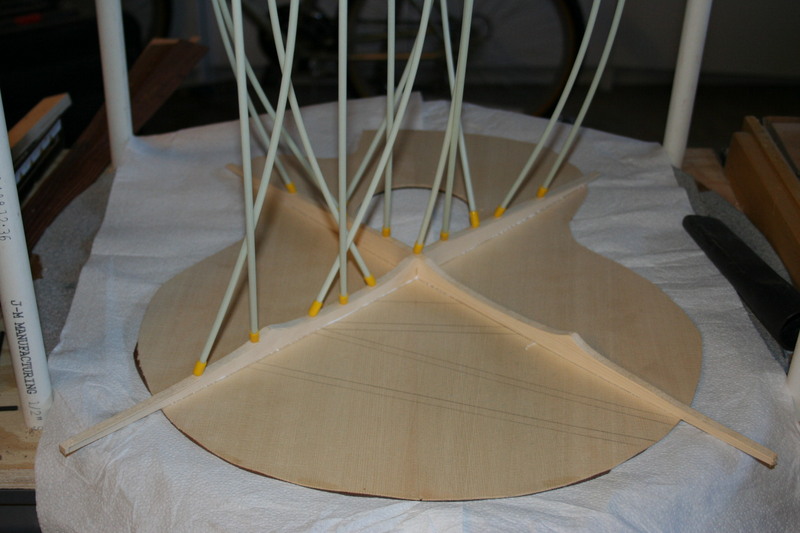

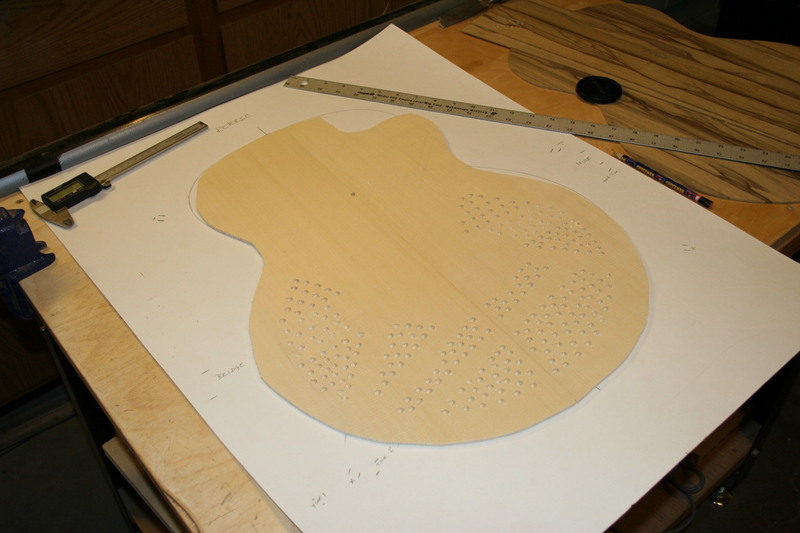

2. the goal was to hollow out most of the lower bout area to reduce weight without sacrificing strength.

3. Instead of using Nomex to reinforce the hollow areas, I decided to route out holes in a honeycomb style removing some material while keeping the top strong. That allowed for less glue usage while utilizing most of the original top.

4. Top was then sanded to thickness and glued onto the redwood top.

The total top thickness is now at about .125" to .115" but the lower bout area, the area that's responsible for most of the top movement, is now about 40% lighter.

I left the center seam untouched, and the brace areas also to ensure and maximize strength.

As of right now tap tone is amazing and I guess we'll know more after the guitar is strung up.

And here is the almost finished guitar!

Thanks for watching!