So I was cutting the taper on the rims at the front on the top last night and thought I would share with you all the way I do it.

Now, I certainly can't take credit for this method, I got if off Charlie Hoffman's website, who says he got the idea from Jim Olson.

Anyway here it is.

Starting with the rims in the mold, I level them out on the sanding rim (I use a flat top, most use a domed top, but this will work for either) but make sure that you have the radius or level on the rims with the linings in place first.

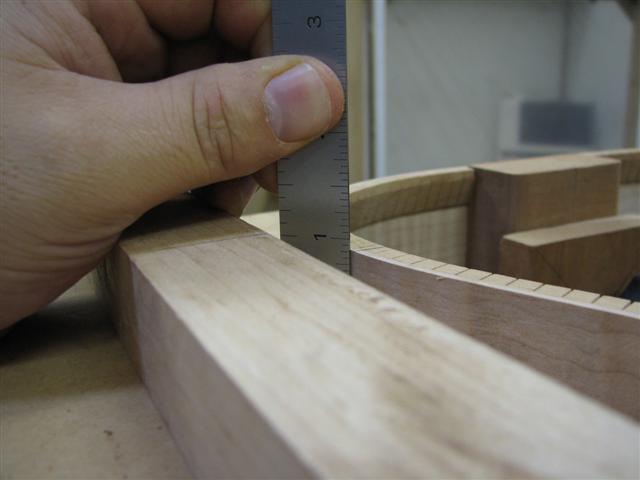

Than I've made up two maple blocks which have the taper of the front bout cut into them (I use 0.75* taper from the front of the sound hole to the front of the body). I double side tape them to the top of the mold with aligning lines I've drawn onto the mold and the block

Next I mark a line on the rims where the line of the front of the sound hole will be.

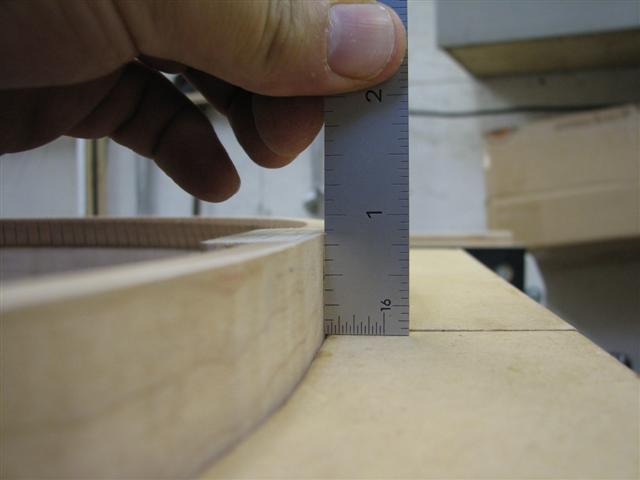

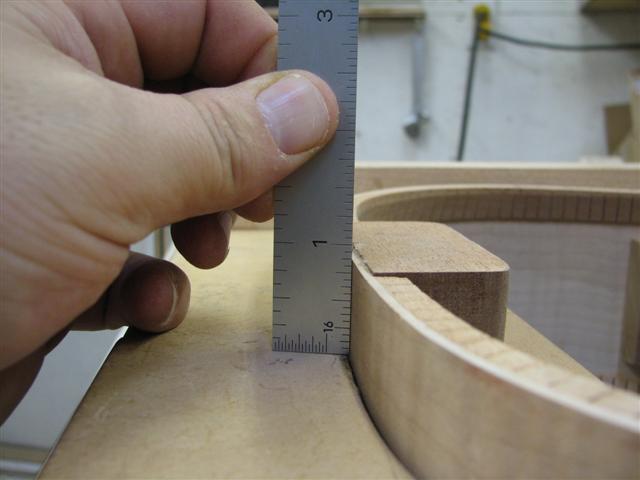

Next, you have to check and make sure that the body is all the same height off the mold all around, so I check with the ruler and adjust at the head and tail block for front and back height and at the soundhole mark for side to side height. Make sure it's right, double and triple measure to get it right. Tap the rim down in the location that's high to get it in place.

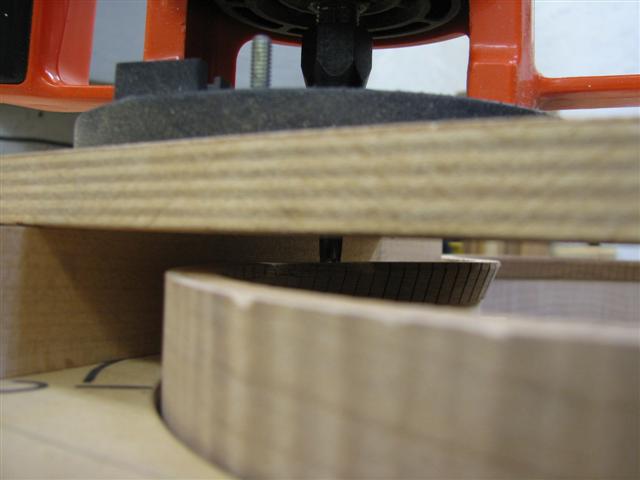

Now tighten the spreaders, check to make sure nothing has moved and your ready to route.

I bolt the router to a sled that runs on the tapered runners. Mark the side of the linings where the line of the top of the sound hole is and adjust the height of the bit till it just touches at the line.

Now you route down along the rims till the taper is cut.

Hope this can help someone out.

(it's Rod though

(it's Rod though