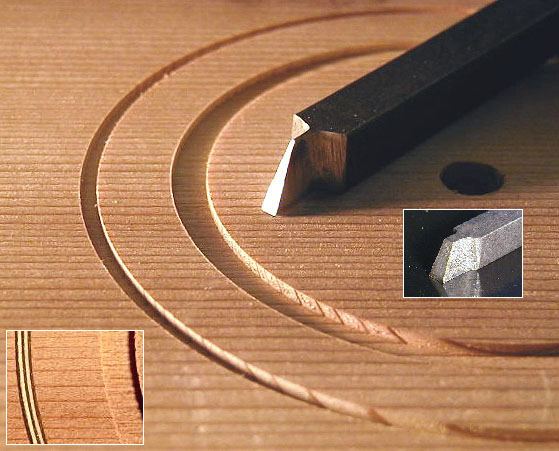

The grinding's not hard at all, and the results are great. You can see the two bit profiles for two channel widths in the photo. Note the relief in the grind.

If you have a balance problem (make sure to use the proper speed <500 rpm if I remember correctly), you can put a counterweight on the other end. I think I used a small piece of lead screwed into the arm of the fly cutter at the opposite end from the bit. I don't remember the details - it was quite a long while ago. Even with that, it's kind of scary in operation, but the results are great.