Have you ever tried running through a swimming pool? no matter how hard you try, you just can't go fast...

Well that's how I feel with this shop, everything that can go wrong has and if something could be back ordered or out of stock it was....

So after 6 weeks of my dust collection parts being on back order I finally got grumpy and worked out a deal with Penn State, we made some mods to my plans and the parts shipped out (a week late but they shipped). In the meantime we traveled to Seattle to attend a Rhino 3d Cad class, when I got there (after a 500 mile drive and a hotel search because the one that looked so good on expedia was a dump to put it kindly), I find out that they made a mistake and signed me up for the Auto-Cad course!!

The plan was to be in seattle this week and then start on the shop next week, well since our trip was a bust, we visited some friends, shopped for boat parts and drove back. On tuesday my order arrived and to my dismay they left out the most critical parts, by this time I was ready to just drive to Penn State and pick it up myself, my wife took over and the next day I finally had all my parts (Penn State made good on the mistake).

During this time I had someone look at the garage door since it's been busted since we moved in, it took him all of 3 minutes to tell me I needed a new one. So after getting the evil eye from the wife another $850 of my shop funds went poof and they will be here monday to install the new door. On the bright side it will have a much higher R-Rating and help keep the shop cooler.

Also I discovered while laying out the ductwork that the shop walls HAD NO INSULATION!!! So a week ago we rented a blower, grabbed some attic insulation and drilled holes in each cavity and filled them with the ground newspaper stuff they blow into attics. Not the best choice but I'm running low on funds and I was afraid of what foam would cost me...

Now here's where the real fun starts, last week we sheduled 4 companies to bid on installing a small air conditioner in the shop. The highest bid was a guy who wanted to install a system in the attic, nice system but it would have ran me $6k, the lowest was a split unit where the ac unit is on the wall (like a space heater) and the condenser sits on a pad, lowest price was $3400

. So I got frustrated and started doing some research and found that you can buy the units online for about $1000, so I was getting charged $2500 for installation!!! You can guess what happened next

I ordered a unit and all the fittings, the instructions are online and I looked them over and it's pretty simple to install. So all it will take is for me to install and then a service guy to come and inspect and charge the unit and I'll be set. The unit I'm getting is rated double for the shop and I did that because some things in the shop generate heat AND (here's the cool part) these units have de-humidifiers built in and can pull 6 gallons an hour!!! Whoo Hooo!!

I was expecting the CNC this week, my machine is done and they have been testing it, apparently they have a new controller board upgrade and I'm the first customer to get one so I have to wait another week while they work out the final details. The cool thing is that they run a FULL set of tests and they promised me it would be perfect before it got here, so even being impatient I'm happy to wait for them to get it all perfect

Finally I spent the week running duct work, if you do this I have some advice:

1. Make sure no small children are around, besides the fact that this is sheet metal and cuts fingers easily it's also a pain and you will make up new swear words.

2. Get someone to help hold things, after I got bonked the 3rd time I dragged my oldest out to help.

3. Buy a metal shear gun, I have an air powered one. I cut one tube by hand and that was it, I headed to Harbor Freight and never looked back.

4. Buy two extra of EVERYTHING... just trust me on this ;)

5. Self tapping metal screws are your friends.....

So despite all my whining the shop is super super close, the last item for us was a new table saw but it's on hold because of the garage door. I have %85 of the ductwork run, I'm wiring it up tomorrow and I have one more order for the last parts and I will button it up this coming week. That just leaves the air-conditioner and a couple of cabinets and I'm done and can start building (actually as soon as the new door is in I'll be able to start).

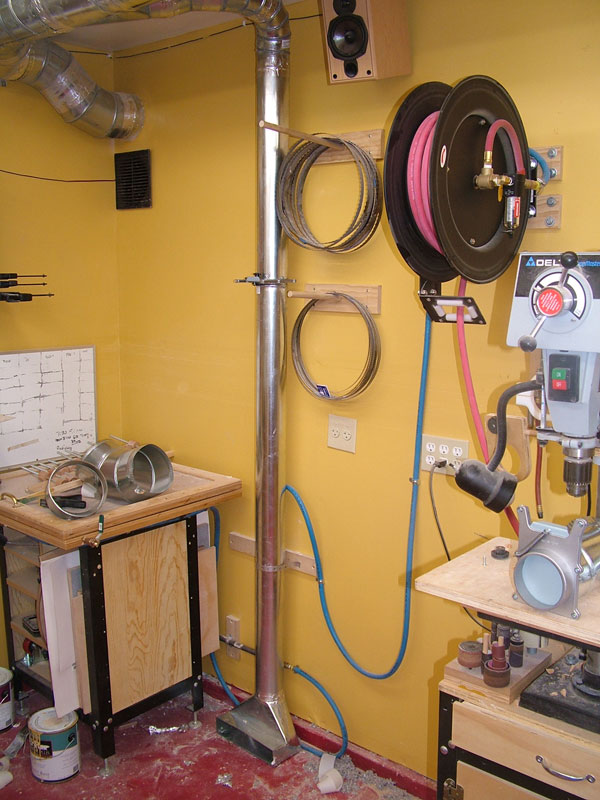

So here are some pictures from today, it's a mess out there but it's SOOOOO close, the system is actually very quiet when running which is very nice, you can't even hear the air compressor unless it's very quiet. It's exactly what I was hoping for, now to finish the details and get busy building, my contract with Adobe is up September 28th and the VERY next day I'm full time in the shop building guitars. Later on I'll post the story about how my first fan fret came back for a new neck, lets just say that players SHOULD NEVER be allowed to work on their guitars....

Let's start here, this is where the ductwork comes into the shop from the outside shed, the black grate is the exhaust that lets air back into the shop, I ran two 7" pipes to accomplish this. But it works and you get quite a breeze from the exhaust.

This is the floor sweep, it allows me to sweep the shop into the dust collection system.

This is the ambient dust collector and on the wall is a double gate unit for hooking up to the rolling tables. The system is writed so that when you pull a gate the Dust Collector comes on automatically and off when you close the gate.

This is right above the workbench, I wanted one for routers and other things and I didn't want to drag collection tubes everywhere.

This is the ductwork running across the shop to the CNC table, the end is open because I need another part to finish this section but all the other pieces are done and ready for the part when it arrives.

This is the new CNC table, it's storing junk right now while I finish the ductwork, but the computer is installed and working

It has storage for tools and drawers for CNC parts.

It also has a roll out shelf for the computer, and a sealed door when closed to keep dust off the PC.

The 'Drawer' above the computer is actually a pull out shelf for a small wireless keyboard (on back-order of course).

I'll post final pics once everything is done and we finish putting stuff away, I talked to Kevin Ryan about his setup table and he was very gracious and I now have a working design for it. As soon as these last little things are done I'll get cracking on that, and once the CNC gets here I'll post pictures of it and it's setup. I was told it comes in a 200 lb wood crate and that I should have some extra hands or a fork lift for it

. Instead I threatened my boys into helping when it gets here

...

I think once the shop is done I'm going to post a sign that says the following:

"Murphy has left the building, he ran out of things to do to me!"

Cheers

-Paul-