I was talking with Woolson the other day and he mentioned that I had been very quiet on the forum, that's true but I've not been idle. Since moving to Idaho we have been working on the new house, getting settled in and planning and working on the shop...

So I figured before Bruce Dickey started asking if I was dead I should post a quick update!!

We laid out the plans for the shop and started working towards getting everything done, the hardest part has been finding reliable contractors to do the various pieces of work that need to be done. They tell you they will be there one day and then call a week later wondering if your still interested!!, finally after some searching we started getting things done.

* First I had the current outlets in the shop expanded to look like this (this was based on a suggestion Bruce had made to me):

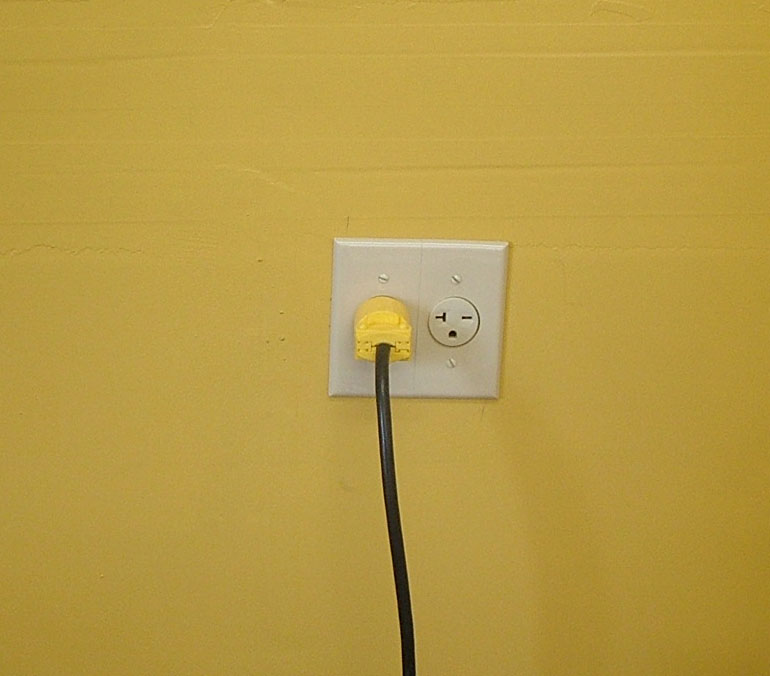

There are four of those around the shop, then I had the electrician wire in 220 for the tools, we ended up with jacks like this:

Those are 220V single jacks that have a horizontal slot so there is NO way you can plug a 110 device into them, they have their own breaker. I can't imagine not running my tools on anything but 220 now, while I'm not building guitars I have been working on other things and the difference is night and day...

Next we installed lighting, after lots of research I ended up with this setup:

There are 8 pairs of 75W 8 Foot lights in the shop, the first time I turned it on it was like walking into the outdoors, at first we thought it was TOO bright but now that I've had the chance to do some work in it I'm not changing a thing. There are no shadows, I can see everything and only need my little lamps for intricate detail work, everything else these lights cover, it was a good investment.

I changed the old door to one that opens outward, added a window so I could let fresh air in and Voila!!. The door no longer opens into my tools, You have to add special hinges so creeps can't take the door off but it was pretty easy to do.

Now for the fun stuff, we had a shed built to house the Dust Collector, air compressor, wood and solvents (paints etc). The *plan* was to fit it into a little alcove next the garage, the end result was that we mis-communicated and I ended up with a monster:

To be fair it's a very nice shed, but I'm going to have to add a gable to that roof to make it fit. I've already got 220 and 110 outlet boxes ready for it, so it's just a matter of doing some custom roofing. We are going to finish the inside where the wood will be and seal it up to like a hotbox for wood storage, the other side will house the mechanicals.

After talking to Woolson about his shop I ordered a Tempest Dust Collector from Penn State, it should be here later this month, we intend on plumbing the whole shop with ductwork. I don't know WHY but I trust Paul so when he say's his dust collector really sucks

The shop is still a mess, but it's getting better every day, the tools are all in position and hooked up. We are about %80 of way done with construction, the last big thing on our list now is building storage into the shop for jigs and other things and then deciding the new workbench plans, for now the old one will be fine to get me going.

I have also at the same time all this is happening have taken the full plunge into the world of CNC, I spent time researching and doing lot's of reading. I ended up buying this machine:

K-2 CNC Machine

I was faced with two options for CNC, go the DIY route or pay the $$$ for one already built. These guys had good comparable prices and have been very easy to work with, this is the single biggest purchase for the shop I have ever made, after a lot of thinking I decided I would rather buy something from a company that has worked out the kinks instead of going DIY and having to build 2 or 3 revisions to get it right.

They spent a good deal of time on the phone with me going over what I wanted to do and had some really good suggestions about how to do things like make parts much more effeciently. I just dropped half down and should have the machine in a couple of weeks, then I have to learn Rhino Cad/Cam (doing that now) and convert my current Turbo-Cad drawings. I plan on making parts, jigs, inlays, rosettes, briges and possibly neck blanks with the machine. My goal is for things like making a mortise and tenon to remove me as much as possible from the picture so I can get consistent results. I can do that now but it requires so much time, with this I can set it up and go work on something else....

I will be posting pictures and information about the setup once I get the machine up and running, that's still a bit away's. I haven't even built a computer for it yet

Just found out about the GAL convention in Tacoma, We are going for sure, is anyone else going or showing there??

Cheers

-Paul-

Sprockett38815.5847569444